| ltem | Unit | Index | |

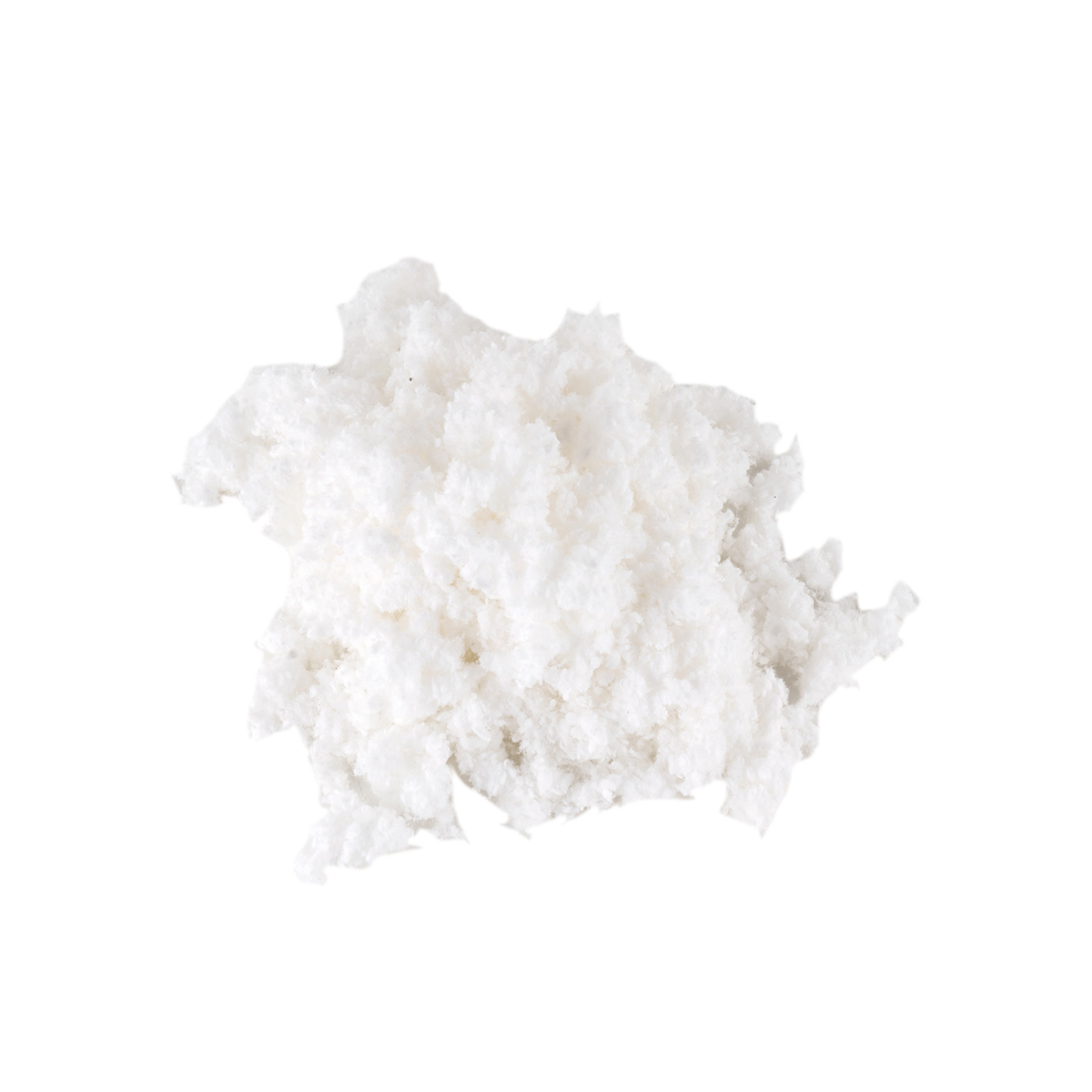

| Appearance | L | _ | White fluffy/flaky fiber |

| Nitrogen CON. | L | % | 11.5~12.2 |

| Transmittance | % | ≥85 | |

| Whiteness | % | ≥82 | |

| Ethanol Damping agent CON. | L | % | 30±2 |

| Water content test | % | Clear In Mixed Solvent | |

| Ash CON. | % | ≤0.2 | |

| Ignition point | C | ≥180 | |

| 80C Thermal-resistance test | Min | ≥10 | |

| Acidity (as H2SO4) | % | ≤0.08 | |

Nitrogen content: 10.7 %- 11.4%

It is soluble in ethanol(= Alcohol)

Its mportant characteristics:

● Formation of fifilms with thermoplastic properties (heat-seal- able, e.g. for coating of aluminum foils)

● Fast solvent evaporation

● Good blending properties with aromatic hydrocarbons

● Good mechanical properties

This specialized nitrocellulose is carefully formulated to deliver outstanding performance and reliability in a variety of applications.

With our L Grade Nitrocellulose, you can expect excellent solubility in both IPA and Ethanol, allowing for seamless integration into your production processes. Whether you require it for coatings, adhesives, or printing inks, our nitrocellulose ensures exceptional clarity, adhesion, and durability, giving your finished products a professional and high-quality appearance.

Furthermore, our L Grade Nitrocellulose offers unmatched stability, ensuring consistent results even under challenging conditions. It is designed to resist yellowing and discoloration, providing long-lasting color retention for your products.

Safety is also a top priority for us. Our L Grade Nitrocellulose is made with utmost care to meet rigorous industry standards. It is manufactured using high-grade materials and undergoes strict quality control processes, ensuring its compliance with safety regulations.

Choose our L Grade Nitrocellulose with IPA or Ethanol and experience the difference in product quality and performance. Boost your productivity and elevate your products to new heights with our reliable and versatile nitrocellulose solution.

| Model | Nitrogen Content | Specification(S) | Solution Concentration | ||

| Method A | Method B | Method C | |||

| L(SS) | 10.7-11.4 | 1/16 | _ | _ | 1.1-1.6 |

| 1/8 | _ | _ | 1.7~2.8 | ||

| 1/4a | _ | _ | 3.1~4.9 | ||

| 1/4b | _ | _ | 5.0~8.0 | ||

| 1/2a | _ | 3.0~6.0 | _ | ||

| 1/2b | _ | 6.1~8.4 | _ | ||

| Methods A, B and C mean that the mass fraction of nitro cotton solution is respectively 12.2%, 20.0% and 25.0%. | |||||

Nitrocellulose can be applied in lacquers for wood, plastic, leather and self-dried volatile coating, can be mixed with alkyd, maleic resin, acrylic resin with good miscibility.

1. Packed in fiber drum (420x700mm).

2. Packed in Iron drum (560x900mm).

| Type | Fiber Drum(KG/Drum) |

| H Grade | 90L-50kgs; |

| 200L-120kgs; |

| CONTAINER | Drum | With Pallets | Without Pallets |

| 20 GP | 90L | 240 Drums | / |

| 40 GP | 405 Drums | 492 Drums | |

| 20 GP | 200L | 80 Drums | 80 Drums |

| 40 GP | 160 Drums | 168 Drums |